Basic Info.

Condition

New

Transport Package

Custom

Specification

200 cm*200 cm*200 cm

Trademark

zhongang

Origin

Chain

HS Code

8431390000

Production Capacity

1000000pieces/Year

Product Description

Product Description

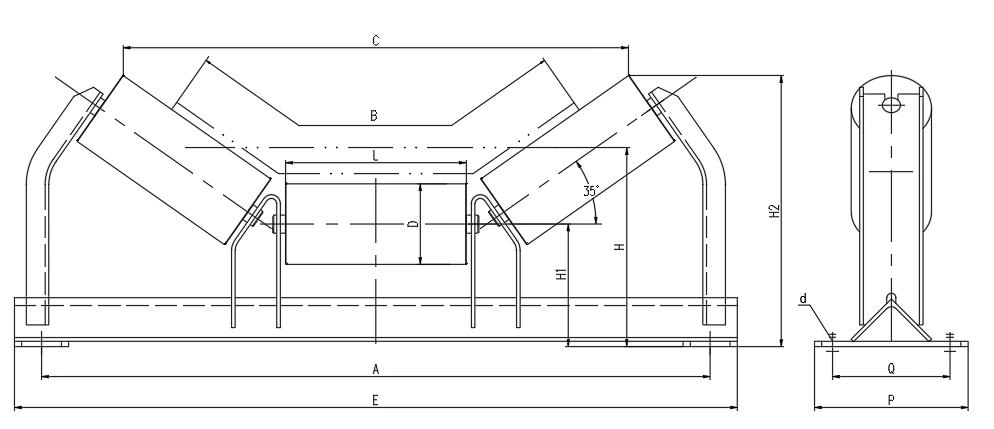

Conveyor accessories Roller support supports the trough roller

TD2A Type Each group can support three rollers

Product Description

35° Related parameters of groove idlers

| Belt Width B | Main size | |||||||||||

| D | L | A | E | C | H | H1 | H2 | P | Q | d | Weight/kg | |

400 | 63.5 | 160 | 600 | 660 | 464 | 185 | 112 | 242 | 170 | 130 | M12 | 9.61 |

| 76 | 460 | 95 | 118 | 254 | 11.4 | |||||||

| 89 | ----- | |||||||||||

500 | 63 | 200 | 740 | 800 | 570 | 200 | 119 | 272 | 70 | 130 | M12 | 12.5 |

| 76 | 567 | 210 | 122 | 28 | 14.9 | |||||||

| 89 | 559 | 220 | 135. | 300 | 15.8 | |||||||

650 | 76 | 890 | 950 | 698 | 225 | 122 | 310 | 170 | 130 | M12 | 16.6 | |

| 89 | 250 | 691 | 235 | 135.5 | 329 | 17.1 | ||||||

| 108 | 584 | 265 | 46 | 346 | 21.3 | |||||||

80 | 89 | 1090 | 1150 | 862 | 245 | 35.5 | 366 | 170 | 130 | M12 | 22.1 | |

| 108 | 315 | 855 | 270 | 146 | 385 | 26.7 | ||||||

| 13 | 841 | 305 | 59 | 408 | 33.2 | |||||||

1000 | 108 | 290 | 1350 | 1038 | 300 | 159 | 437 | 220 | 170 | M16 | 38.0 | |

| 133 | 380 | 1023 | 325 | 173. | 461 | 45.5 | ||||||

| 59 | 1020 | 370 | [90 | 49 | 57.1 | |||||||

1200 | 108 | 1540 | 1600 | 262 | 335 | 176 | 50 | 260 | 200 | M16 | 50.5 | |

| 133 | 465 | 1248 | 360 | 190.5 | 521 | 59.2 | ||||||

| 159 | 244 | 390 | 207.5 | 556 | 72.4 | |||||||

400 | 108 | 1740 | 1810 | 1433 | 350 | 184 | 546 | 280 | 220 | M16 | 56.2 | |

| 133 | 530 | 1419 | 380 | 98.5 | 573 | 65.6 | ||||||

| 159 | 1415 | 410 | 215. | 602 | 87.8 | |||||||

1600 | 13 | 990 | 2060 | [603 | 430 | 205 | 619 | 300 | 240 | M16 | 85.3 | |

| 159 | 600 | 1598 | 460 | 220 | 646 | 100.8 | ||||||

| 194 | ------ | |||||||||||

1800 | 132 | 670 | 2190 | 2260 | 1788 | 455 | 215 | 669 | 300 | 240 | M16 | 98.3 |

| 159 | 1784 | 485 | 230 | 696 | 114.8 | |||||||

| 194 | 1784 | 525 | 255 | 739 | 152.3 | |||||||

2000 | 133 | 750 | 2420 | 2490 | 999 | 460 | 215 | 715 | 300 | 240 | M16 | 107.1 |

| 59 | 1995 | 500 | 230 | 742 | 125.4 | |||||||

| 194 | 995 | 540 | 255 | 785 | 165.9 | |||||||

2200 | 133 | 800 | 2720 | 2800 | ||||||||

| 159 | ||||||||||||

| 194 | ||||||||||||

2400 | [59 | 900 | 3020 | 3110 | ||||||||

| 194 | ||||||||||||

| 219 | ||||||||||||

Factory display

Laser cutting machine. The computer controls the

precise data, and the cutting surface is smoother.

precise data, and the cutting surface is smoother.

CNC bending machine can precisely control the bending

Angle and bending radius

Angle and bending radius

Manual operation of welding points by skilled workers is

more secure

more secure

Installation instructions

The installation steps of the conveyor support are as follows:

1. Determine the installation position of the support: according to the needs of the conveyor, determine the installation position of the support, and consider the length, height, weight and other factors of the conveyor.

2. Obtain installation materials: Obtain required materials, such as bolts, nuts, Angle steel, and channel steel.

3. Install the Angle steel bracket: Cut and weld the Angle steel according to the requirements of the device installation drawings, and then fix it to the foundation.

4. Install the channel beam: Install the channel beam above the Angle steel support and fix it to the Angle steel support.

5. Install the column: Fix the column on the channel steel beam, pay attention to the position and Angle of the column, and ensure that the column is perpendicular to the channel steel beam.

6. Install adjusting bolts: Install adjusting bolts on the Angle steel support to adjust the height and levelness of the conveyor.

7. Install the support rod: At the connection of the support and the conveyor, install the support rod to support the conveyor and prevent the deformation and shaking of the conveyor.

8. Adjust the position of the support: After the installation is complete, fine-tune the position of the support according to the need to make the conveyor run smoothly.

When installing a conveyor support, perform operations according to the installation drawings and ensure installation quality to ensure the normal and safe running of the conveyor.