Basic Info.

Model NO.

Screw Conveyor

Transport Package

Nude

Trademark

XINTU

Origin

China

HS Code

842839

Product Description

Conveyor industrial automatic screw feeder portable screw conveyor machine for cement

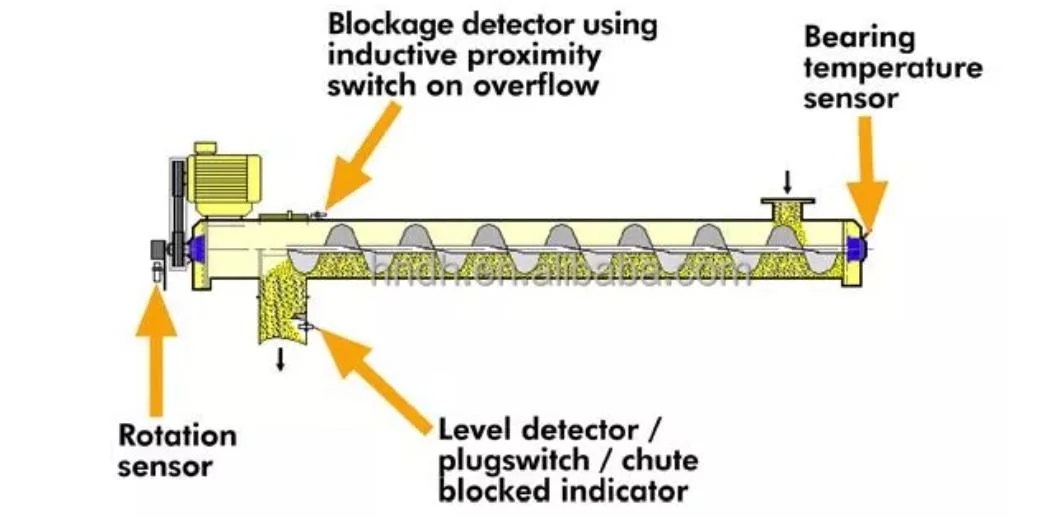

Work principle:

Screw conveyor can transport with the help of rotating spiral blade,or by sipral side and the tank that itself can rotate.The powder material used in dry mortar production line is transmitted by screw conveyor,by controllong the spiral blade rotation and stop to control the powder material feeding,the conveyor must be conducted in a completely sedled cavity body,in order to avoid polluting the environmrnt and conveying material be affected agglomerate with damp,generally adopts tubular screw conveyor to transport cenment and compound material.

In general,screw conveyor are at a certain angle to work,the angle up to 45°.A larger angle can be up to 60°.The different length of the screw conveyor can be got by increasing or reducing the standard sections,but the length of each screw should not exceed the maximum length of 14m.Spiral relay can be used in longer transported distances.

Work principle:

Screw conveyor can transport with the help of rotating spiral blade,or by sipral side and the tank that itself can rotate.The powder material used in dry mortar production line is transmitted by screw conveyor,by controllong the spiral blade rotation and stop to control the powder material feeding,the conveyor must be conducted in a completely sedled cavity body,in order to avoid polluting the environmrnt and conveying material be affected agglomerate with damp,generally adopts tubular screw conveyor to transport cenment and compound material.

In general,screw conveyor are at a certain angle to work,the angle up to 45°.A larger angle can be up to 60°.The different length of the screw conveyor can be got by increasing or reducing the standard sections,but the length of each screw should not exceed the maximum length of 14m.Spiral relay can be used in longer transported distances.

Technical Parameters of screw conveyer:

Model | LSY165 | LSY219 | LSY273 | LSY325 | LSY400 | ||

DiameterΦ(mm) | 165 | 185 | 237 | 285 | 362 | ||

Outside diameterΦ(mm) | 194 | 219 | 273 | 325 | 402 | ||

Speed(r/min) | 308 | 260 | 200 | 170 | 170 | ||

Max conveying capacity(t/h) | 25 | 40 | 60 | 90 | 120 | ||

Max conveying length L(mm) | 15 | 18 | 25 | 25 | 25 | ||

Working angle(a) | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | ||

Electric | Type | L≤9 | Y132S-4 | Y132M-4 | Y160L-6 | Y180M-4 | Y180M-4 |

| Power |

| 5.5 | 7.5 | 11 | 18.5 | 18.5 |

| Type | L>9 | Y132M-4 | Y160M-4 | Y180L-6 | Y180L-4 | Y180L-4 |

| Power |

| 7.5 | 11 | 15 | 22 | 22 |

Feature:

Feature: 1.Simple structure,easy operation

2.Small section of whole machine,being suitable for horizontal or tilted transportation

3.Stable transportation so as to play a good role

4.Excellent sealing performance so as to have advantages under he situation that has more dust and made higher request on the environment and to avoid the dust phenomenon in the process of transportation