Basic Info.

Model NO.

02

Warranty

2 Years

Color

Blue

Customized

Customized

Condition

New

Voltage

380kv

Power

2000kw

Width or Diameter

200m-8000m

Weight (Kg)

1000 Kg

Steel Pipe

Q235

Transport Package

Steel-Strcuture Pallet or Wooden Case.

Trademark

ZOOMRY

Origin

Hebei Province

Production Capacity

2000 Meter/Meters Per Month

Product Description

Product Description Long distance turning belt conveyor

Advantage

Advantage Professional design team, which can design according to the actual needs of customers;

Optimize the plan by using different terrains and combinations of different accessories;

The cost can be saved by more than 20% through the optimized plan.

Specification

Details

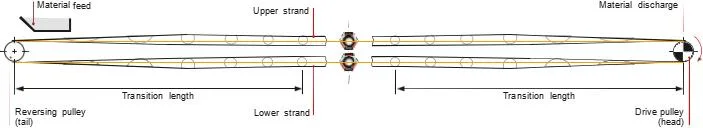

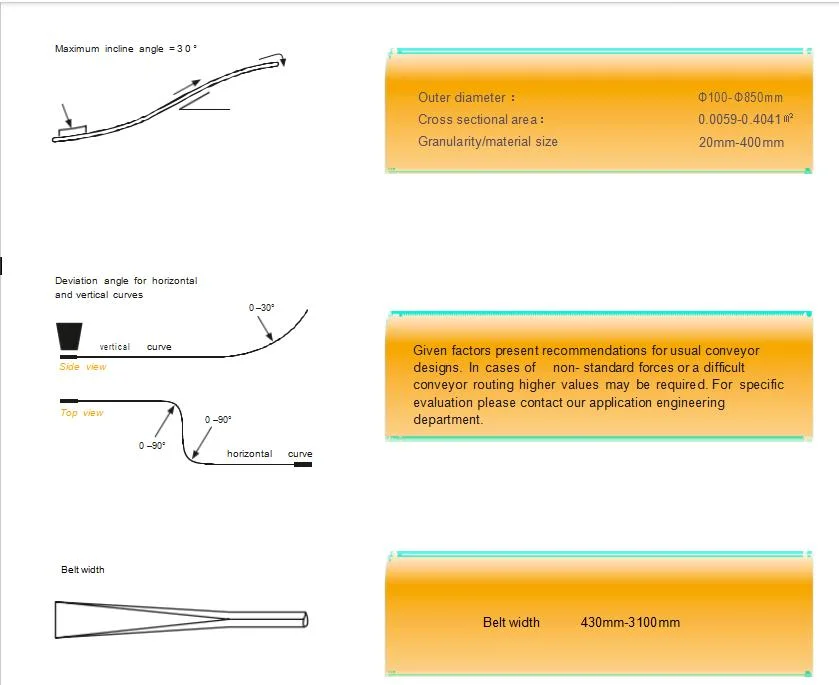

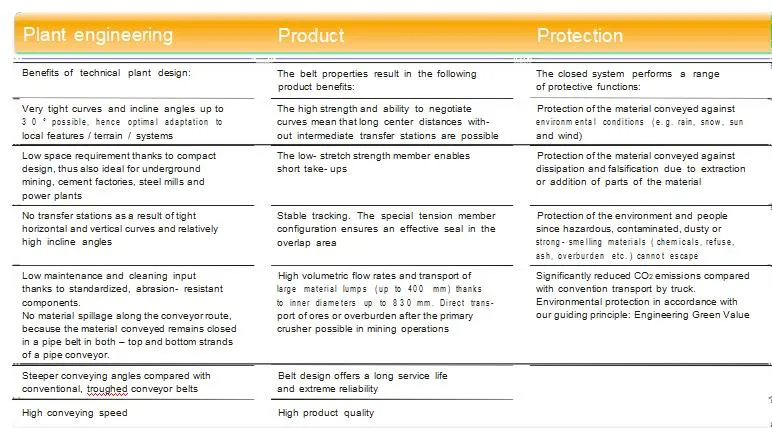

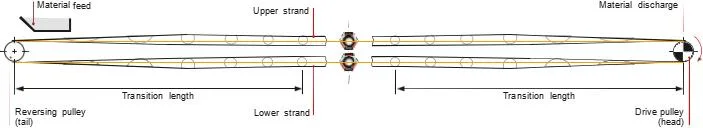

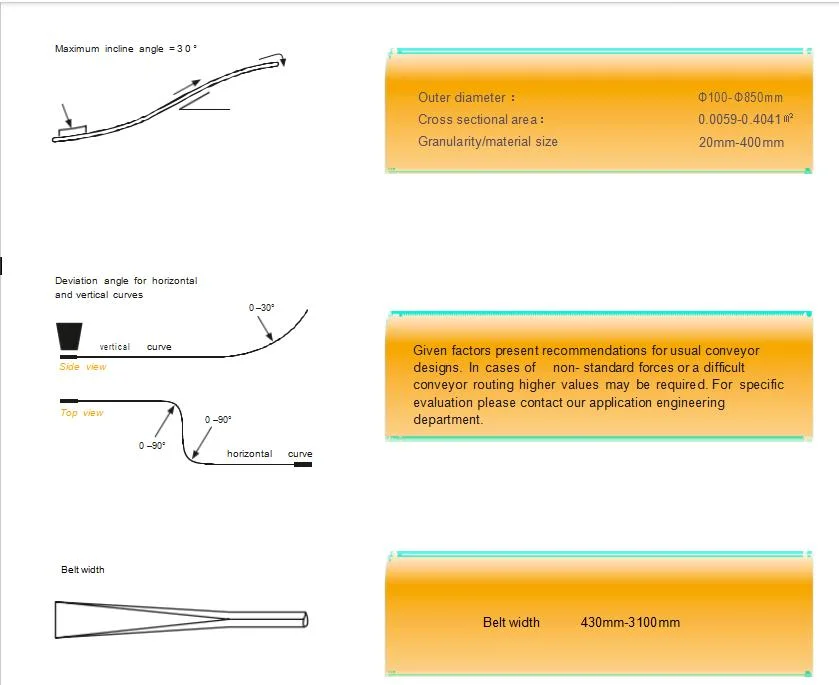

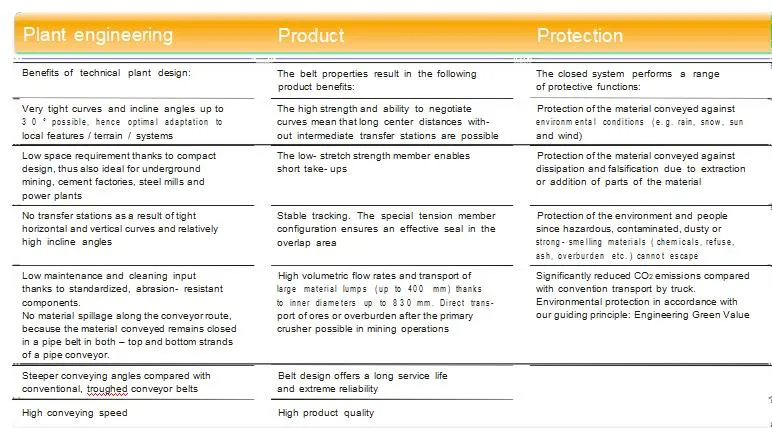

Design and function of the pipe conveyor system

Properties of the pipe belt conveyor system

In addition to consistent quality and technical reliability, highly engineered pipe belt conveyor systems offer a range of other benefits.

Belt Sway Switch

Detect whether the belt is deviating and send out a slight alarm or shutdown signal. Deviation will damage the belt and cause safety accidents. Deviation switches need to be purchased and installed in pairs

Pull Cord Switch

Pull the wire rope to realize the switch action, which is used for emergency shutdown. It is a safety switch and is arranged along the entire length of the fuselage.

When an emergency occurs on the belt conveyor, the conveyor can be stopped urgently at any position. There are single-sided and double-sided arrangements. They are generally used in conjunction with walkways.

Zero Speed Switch

Detect whether the belt is slipping with the head roller. After slippage occurs, the Conveyor Belt speed will decrease. When the transport volume is overloaded, the belt tension is insufficient, or the rubber layer of the driving roller is worn out, slippage may easily occur. The conveyor belt speed can be monitored (also the rotational speed is calculated) or the drum rotation speed can be monitored.

If the belt conveyor in the stacker encounters an unexpected situation, such as a power outage or a broken wire rope, the stacker has a self-protection function:

1. The winch motor has a self-locking function of 0.01 seconds when the power is cut off

2. The stacker has 2 mechanical mechanisms If stuck, the internal unit will not slip to the bottom all at once. There are two designs in the middle to prevent jamming.

The large-inclination conveyor mainly increases the friction between the material and the conveyor belt by increasing the pressure or contact surface between the material and the conveyor belt, so that the material will not slide down during the process of increasing the inclination angle, occupying a small area but have high operating efficiency.

EPC cases

Inner Mongolia MengXi Group Cement Plant 2013

Material type: Limestone

Capacity: 2200t/h

Belt length: 4650m

Belt width: 1400mm

DTIIA, TD75, CEMA and other standard conventional belt conveyors are used in factories, production lines, raw material factories, loading stations and other places in various industries.

HuaXia JianLong Group HeBei 2014

Capacity: 2600t/h

Belt length: 2300m+780m

Curve angle: 45°

Redius of curvature: 500m

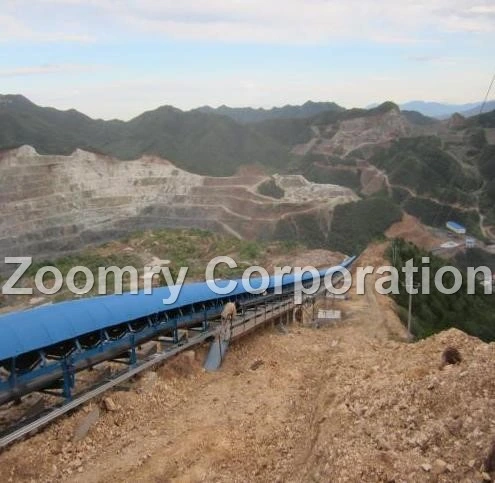

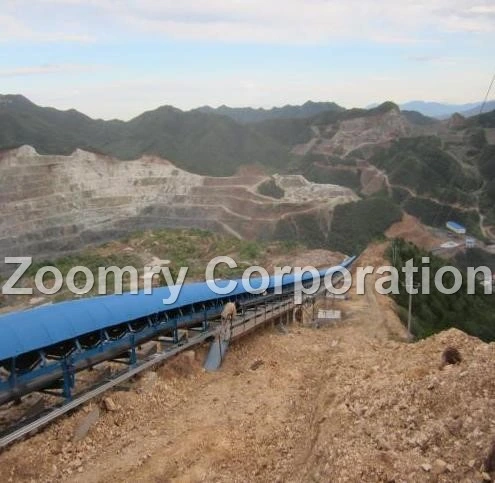

Project time: 2018

Region: Chengde, Hebei Province

Material: iron ore

Environmental conditions: undulating mountainous terrain, very demanding on selecting the conveyor route

Conveyor length: 3300m

Belt width: 1400mm

Handling capacity: 2000t/h

Solution: long-distance curved belt overland conveyor (3 horizontal curves with radius of 1200m, motor power 63kW×4, ST3150/1400 steel cord Conveyor Belt, lifting height 140m)

Our after-sales service:

1)Installation guide;

2)Provide drawings and instructions;

3)On-site guidance of dispatched engineers;

4)The machine has a long warranty of 2 years ;Roller warranty 50,000 hours.

Compared with most manufacturers, we can provide long-distance conveyor belt turning technology;

The solution is flexible and adaptable, suitable for more terrain;

Giving customers more choices.

Can achieve a transmission distance of more than 20 kilometers and a maximum inclination of 35°;

Can achieve a transmission distance of more than 20 kilometers and a maximum inclination of 35°;

Can undertake large and difficult projects;

Provide customers with one-stop service.

Have undertaken many projects, with an average operating time of more than ten years;

The times of repairs and replacement parts is far below the industry standard;

Maintenance costs are reduced by about 30%.

| Belt Width | 800mm;914mm(36'');1000mm;1200;1400mm;1600mm; (Customized) |

| Length | 5km;10km;15km;20km;25km;30km (Customized) |

| Inclination | -30°~+30° |

| Capacity | 0-15000m3/h |

| Material particle size | ≤300mm |

| Belt Speed | 0.6~4.5m/s |

| Pulley Size | 400mm~1800mm(Diameter) |

| Idler Size | 89mm~219mm(Diameter) |

Details

Design and function of the pipe conveyor system

Properties of the pipe belt conveyor system

In addition to consistent quality and technical reliability, highly engineered pipe belt conveyor systems offer a range of other benefits.

Belt Sway Switch

Detect whether the belt is deviating and send out a slight alarm or shutdown signal. Deviation will damage the belt and cause safety accidents. Deviation switches need to be purchased and installed in pairs

Pull Cord Switch

Pull the wire rope to realize the switch action, which is used for emergency shutdown. It is a safety switch and is arranged along the entire length of the fuselage.

When an emergency occurs on the belt conveyor, the conveyor can be stopped urgently at any position. There are single-sided and double-sided arrangements. They are generally used in conjunction with walkways.

Zero Speed Switch

Detect whether the belt is slipping with the head roller. After slippage occurs, the Conveyor Belt speed will decrease. When the transport volume is overloaded, the belt tension is insufficient, or the rubber layer of the driving roller is worn out, slippage may easily occur. The conveyor belt speed can be monitored (also the rotational speed is calculated) or the drum rotation speed can be monitored.

If the belt conveyor in the stacker encounters an unexpected situation, such as a power outage or a broken wire rope, the stacker has a self-protection function:

1. The winch motor has a self-locking function of 0.01 seconds when the power is cut off

2. The stacker has 2 mechanical mechanisms If stuck, the internal unit will not slip to the bottom all at once. There are two designs in the middle to prevent jamming.

The large-inclination conveyor mainly increases the friction between the material and the conveyor belt by increasing the pressure or contact surface between the material and the conveyor belt, so that the material will not slide down during the process of increasing the inclination angle, occupying a small area but have high operating efficiency.

EPC cases

Inner Mongolia MengXi Group Cement Plant 2013

Material type: Limestone

Capacity: 2200t/h

Belt length: 4650m

Belt width: 1400mm

DTIIA, TD75, CEMA and other standard conventional belt conveyors are used in factories, production lines, raw material factories, loading stations and other places in various industries.

HuaXia JianLong Group HeBei 2014

Capacity: 2600t/h

Belt length: 2300m+780m

Curve angle: 45°

Redius of curvature: 500m

Project time: 2018

Region: Chengde, Hebei Province

Material: iron ore

Environmental conditions: undulating mountainous terrain, very demanding on selecting the conveyor route

Conveyor length: 3300m

Belt width: 1400mm

Handling capacity: 2000t/h

Solution: long-distance curved belt overland conveyor (3 horizontal curves with radius of 1200m, motor power 63kW×4, ST3150/1400 steel cord Conveyor Belt, lifting height 140m)

Our after-sales service:

1)Installation guide;

2)Provide drawings and instructions;

3)On-site guidance of dispatched engineers;

4)The machine has a long warranty of 2 years ;Roller warranty 50,000 hours.