Basic Info.

Model NO.

ZL

Transport Package

Anticorrosion Wooden Cases

Specification

According to the model

Trademark

BOEEP

Origin

Jiangsu China

HS Code

8421299090

Production Capacity

400sets/Year

Product Description

Sewage Treatment Suspended Solids Removal Rotary Filter Press

Product Application:

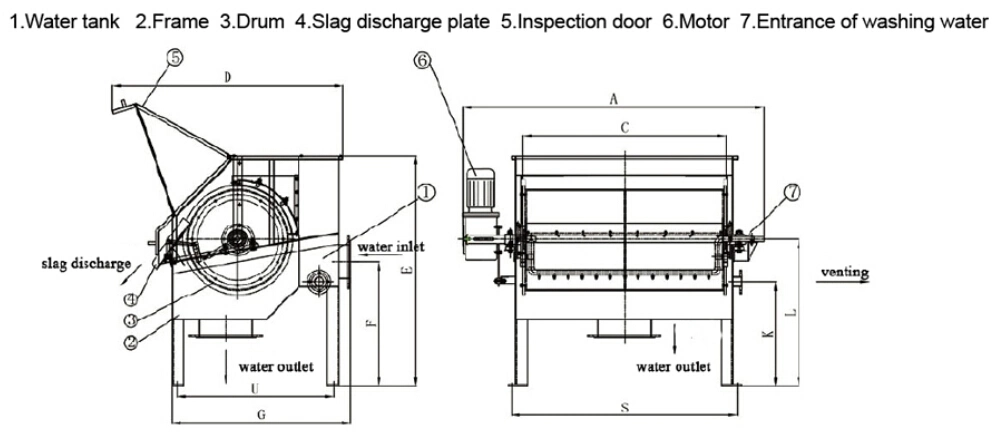

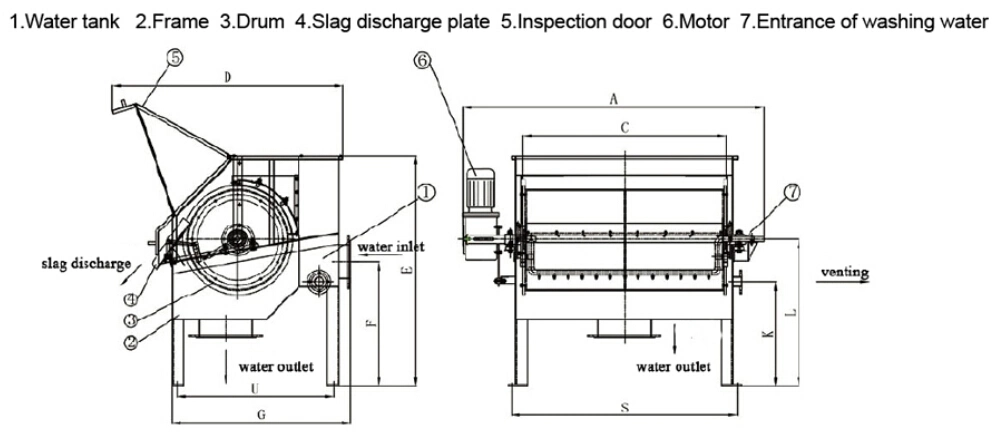

Structure of sludge dewatering machine:

Maintenance and repairing

1. When initial use, people must be sent to track and observe whether there is abnormal noise, the bar frame beats, the grid blocks, the dregs output is smooth and each fastener is fastened or not.

2. Regularly inspection of the above situations should be taken when running for a long time.

3. The oil level of the reducer should be controlled strictly. The oil should be replaced after 6 months when initial use, and then replaced once a year. This equipment uses the 70# ~ 120# medium pressure industrial gear oil.

4. Let the equipment idle for a period of time before stopping it every time. Do not stop the equipment until the dregs on the grid are cleaned.

5. Some dead space may accumulate dregs after long-term running, manual clearing need to be done regularly.

6. Each place of the equipment should be cleaned up if it stops running for a long time. The equipment needs a regular rotation (once 30 days generally).

Working Shop:

Any interest or demand, pls contact us freely. Thank you!

Your satisfaction is our forever wish!

BOEEP: The leading provider of treatment equipment for water and wastewater industries in China, heading to all over the world.

Specification:

1. Simple structure, high reliability.

2. Compact structure; smaller covering area with the same treatment capacity.

3. The surface of the drum is made of wedge grid, and has excellent hydraulic characteristics.

General description for Drum Filter :

Drum Filter is composed of inspection door, drum, water storage tank, flushing device, dregs discharge board and bar frame. It is designed for wastewater treatment plants of small and medium cities or industries, and is a device which can remove solid suspended matter continuously and effectively and is mainly used in pretreatment of wastewater or industrial sifting process.

In some wastewater treatments, 30% to 60% of the organic or inorganic solid suspended matter will be removed after filtering, and reducing greatly the subsequent work load.

When the Drum Filter works, the reducer drives the bar frame to rotate. The floater in the sewage will leave on the grid through filtering by the bar frame, and then fall on the dregs discharge board by the rotation of bar frame. If the dregs block the bar frame, use the flushing device to flush the grid, then the dregs fall on the dreg discharge board and slip into the junk car or conveyor.

Specification:

1. Simple structure, high reliability.

2. Compact structure; smaller covering area with the same treatment capacity.

3. The surface of the drum is made of wedge grid, and has excellent hydraulic characteristics.

General description for Drum Filter :

Drum Filter is composed of inspection door, drum, water storage tank, flushing device, dregs discharge board and bar frame. It is designed for wastewater treatment plants of small and medium cities or industries, and is a device which can remove solid suspended matter continuously and effectively and is mainly used in pretreatment of wastewater or industrial sifting process.

In some wastewater treatments, 30% to 60% of the organic or inorganic solid suspended matter will be removed after filtering, and reducing greatly the subsequent work load.

When the Drum Filter works, the reducer drives the bar frame to rotate. The floater in the sewage will leave on the grid through filtering by the bar frame, and then fall on the dregs discharge board by the rotation of bar frame. If the dregs block the bar frame, use the flushing device to flush the grid, then the dregs fall on the dreg discharge board and slip into the junk car or conveyor.

Product Application:

- Municipal water and wastewater treatment plants

- Agricultural/fishery community wastewater treatment plants

- Industrial waste treatment plants

- Food/beverage production plants

- Dairy farming/Meat processing plants

- Chemicals manufacturing plants

- Machinery manufacturing/Metal processing plants

- Laundry wastewater

- Other plants requiring dewatering machine (paper manufacturing, building material manufacturing, oilfield associated water accompanied with crude oil mining, etc.)

| Model | Water inlet pipe | Water output pipe | Washing pipe | A | C | D | E | F | G | H | K | L | S | U |

| ZL350×600 | DN100 | DN150 | DN15 | 1195 | 600 | 880 | 1100 | 620 | 660 | 1055 | 540 | 760 | 735 | 550 |

| ZL610×610 | DN150 | DN200 | DN15 | 1290 | 610 | 1385 | 1395 | 750 | 1100 | 940 | 630 | 885 | 760 | 945 |

| ZL610×1220 | DN200 | DN250 | DN20 | 1940 | 1220 | 1385 | 1595 | 950 | 1100 | 604 | 830 | 1085 | 1360 | 945 |

| ZL610×1830 | DN250 | DN300 | DN25 | 2425 | 1830 | 1385 | 1745 | 1100 | 1100 | 940 | 980 | 1235 | 2025 | 945 |

| ZL800×1830 | DN300 | DN350 | DN25 | 2425 | 1830 | 1450 | 1935 | 1200 | 1300 | 1450 | 980 | 1330 | 2025 | 1255 |

| Gird gap (mm) | 0.25 | 0.5 | 0.75 | 1 | 1.5 | 2.5 | Diameter of Drum(mm) | Length of Drum(mm) | Power(KW) | ||||

| Model | Capacity(m³/h) | ||||||||||||

| ZL350×600 | 8 | 15 | 20 | 25 | 32 | 42 | 350 | 600 | 0.25 | ||||

| ZL610×610 | 33 | 60 | 81 | 100 | 130 | 170 | 610 | 610 | 0.55 | ||||

| ZL610×1220 | 65 | 120 | 162 | 200 | 260 | 340 | 610 | 1220 | 0.75 | ||||

| ZL610×1830 | 100 | 180 | 243 | 306 | 397 | 520 | 610 | 1830 | 0.75 | ||||

| ZL800×1830 | 175 | 315 | 436 | 535 | 695 | 912 | 800 | 1830 | 1.1 | ||||

Structure of sludge dewatering machine:

Maintenance and repairing

1. When initial use, people must be sent to track and observe whether there is abnormal noise, the bar frame beats, the grid blocks, the dregs output is smooth and each fastener is fastened or not.

2. Regularly inspection of the above situations should be taken when running for a long time.

3. The oil level of the reducer should be controlled strictly. The oil should be replaced after 6 months when initial use, and then replaced once a year. This equipment uses the 70# ~ 120# medium pressure industrial gear oil.

4. Let the equipment idle for a period of time before stopping it every time. Do not stop the equipment until the dregs on the grid are cleaned.

5. Some dead space may accumulate dregs after long-term running, manual clearing need to be done regularly.

6. Each place of the equipment should be cleaned up if it stops running for a long time. The equipment needs a regular rotation (once 30 days generally).

Working Shop:

Any interest or demand, pls contact us freely. Thank you!

Your satisfaction is our forever wish!