- Overview

- Product Description

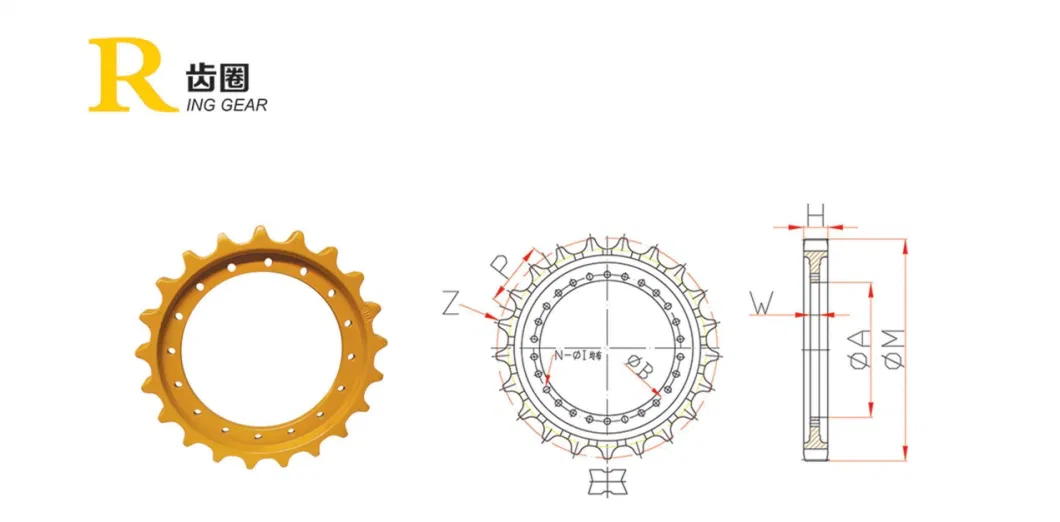

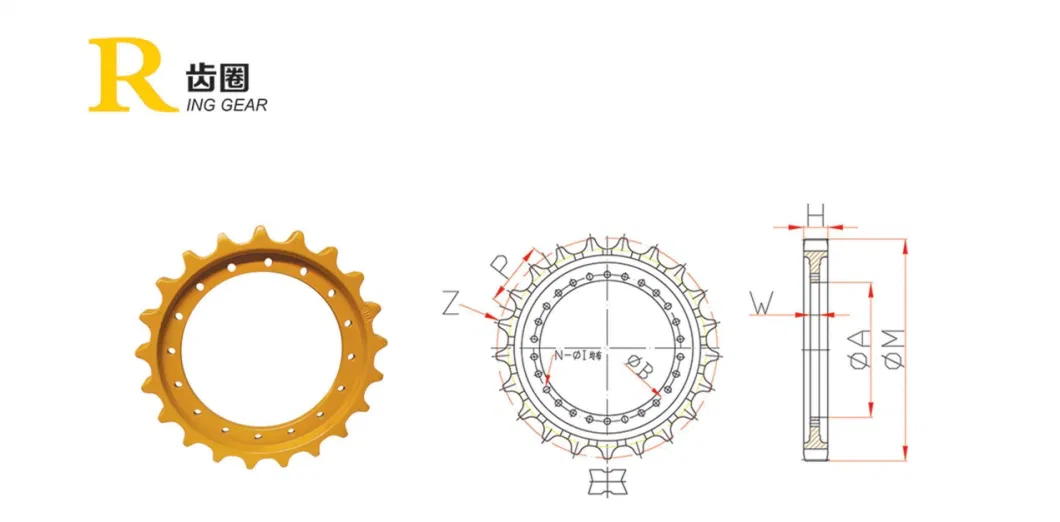

- Structure Of Products

- Detailed Photos

- Product Parameters

- Our Advantages

- Related Products

- Company Profile

- FAQ

Basic Info.

Model NO.

Sprocket

Product Name

Sprocket

Keywords

Excavator Drive Sprocket

Material

40mn/35mnb

Finish

Smooth

Colors

as Per to Customer′s Request

Technique

Forging &Casting

Weight

10-50kg

Surface Hardness

HRC50-56 , Deepth:4mm-10mm

Size

Standard or Customized

Process

Forging Casting

Test Report

Provided

Shape

Round

Quality

100% Tested

OEM

OEM Services Provided

MOQ

1 Piece

Transport Package

Pallet or Customized

Specification

standard or Customized

Trademark

OLA or OEM

Origin

China

HS Code

84314999

Production Capacity

8000PCS/Month

Product Description

OLA Mechanical Machinery Suppliers Mini Excavator Drive Sprocket Wheel China E120B Excavator Parts Sprocket

The Excavator Drive Sprocket, Also Known As The Excavator Sprocket Wheel, is another crucial component of an excavator's Undercarriage System. It is connected to the final drive motor and engages with the excavator's Track Chain.

The Drive Sprocket Is Typically Located At The Rear Of The Excavator And Is Responsible For Driving The Tracks And Propelling The Machine Forward Or Backward. The Sprocket Is Comprised Of Teeth That Mesh With The Links Of The Track Chain, Enabling The Excavation Machine To Move.

Like Other Components Of The Undercarriage System, The Drive Sprocket Is Made From Durable Materials, Such As Steel. It Undergoes Heat Treatment Processes To Enhance Its Strength And Wear Resistance, As It Experiences Substantial Forces And Friction During Operation.

The Drive Sprocket Is Typically Located At The Rear Of The Excavator And Is Responsible For Driving The Tracks And Propelling The Machine Forward Or Backward. The Sprocket Is Comprised Of Teeth That Mesh With The Links Of The Track Chain, Enabling The Excavation Machine To Move.

Like Other Components Of The Undercarriage System, The Drive Sprocket Is Made From Durable Materials, Such As Steel. It Undergoes Heat Treatment Processes To Enhance Its Strength And Wear Resistance, As It Experiences Substantial Forces And Friction During Operation.

| Parame Code | A | M | P | H | W | N-φ | Z |

| DH55/R60 | 250 | 465 | 135 | 42 | 18 | 12-φ17 | 21 |

| DH130 | 325 | 592 | 171 | 56 | 18.7 | 15-φ17.5 | 21 |

| DH170 | 362 | 645 | 171 | 64 | 21.6 | 21-φ18 | 23 |

| DH370 | 490 | 740 | 216 | 90 | 33 | 28-φ21 | 21 |

| DH400 | 490 | 740 | 216 | 90 | 33 | 28-φ21 | 21 |

| DH220/R225-7 | 402 | 660 | 190 | 68 | 18 | 30-φ16 | 21 |

| DH280 | 450 | 760 | 203 | 74 | 25.5 | 16-021.5 | 23 |

| DH450 | 325 | 590 | 171 | 52 | 22.4 | 15-φ17 | 21 |

| E55 | 230 | 424 | 135 | 49 | 14.5 | 9-φ15.5 | 19 |

| E70B | 265 | 555 | 135 | 38 | 18 | 12-φ16 | 25 |

| E70B-3 | 288 | 555 | 135 | 38 | 17 | 12-φ16 | 25 |

| E120B | 346 | 600 | 171.5 | 52 | 21 | 15-φ18 | 21 |

| E200B | 415 | 660 | 190 | 63 | 22.3 | 14-φ21.5 | 21 |

| E305.5B | 230 | 428 | 135 | 49 | 16 | 12-φ15 | 19 |

| E320 | 456 | 660 | 190 | 65 | 23 | 16-φ21 | 21 |

| E325 | 450 | 697 | 203 | 75 | 27 | 18-φ21.5 | 21 |

| E330 | 515 | 813 | 216 | 80.5 | 28 | 16-φ21.5 | 23 |

| E345 | 577 | 810 | 216 | 86 | 23 | 20-φ25 | 23 |

| E450 | 561 | 885 | 216 | 86 | 26 | 24-φ27 | 25 |

| E300B | 450 | 770 | 190 | 70 | 25 | 16-φ21 | 25 |