Basic Info.

Model NO.

width 250~4000mm

Strength

6-25MPa

Cover Thickness Upper

1.5-12

Belt Width

500-2500mm

Ply Thickness

1.45mm/Ply

Cover Thickness Uppertlower

0-4.5

Certificate

ISO9001, ISO14001, SGS, BV

Standards

ISO, GB, DIN, BS, as, Rma, Jisk, Sans

Strength Class

160-3000kn/M

Application

Quarry/Port/Mining/Coal

Kinds

Cc, Nn, Ep, St, VV, Vc, PVC, Pcg

Key Words

Rubber Conveyor Belt

Processing Service

Moulding, Cutting

Fabric Structure Weft

Polyamide

Package

Rolls

Transport Package

Pallet or Steel Frame

Specification

NN100, NN150, NN200, NN250, NN300, NN400, NN500,

Trademark

XinRiSheng

Origin

China

HS Code

4010120000

Production Capacity

50000m Per Month

Product Description

We are a manufacturer of quality conveyor belts. The product range consists of all types of conveyor belts in rubber, PVC/PU, and sidewalls. Apart from the traditional conveyor belts. we offer a wide range of special conveyor belts and profile belts.We serve our customers in more than 50 countries world wide.

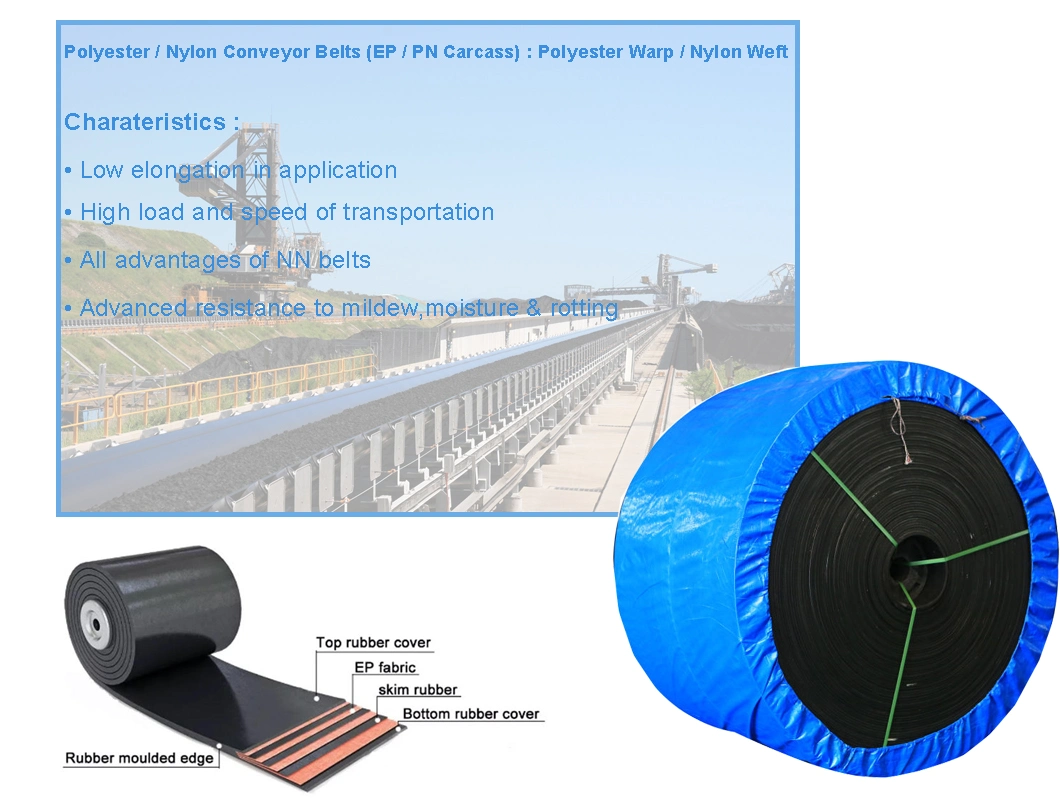

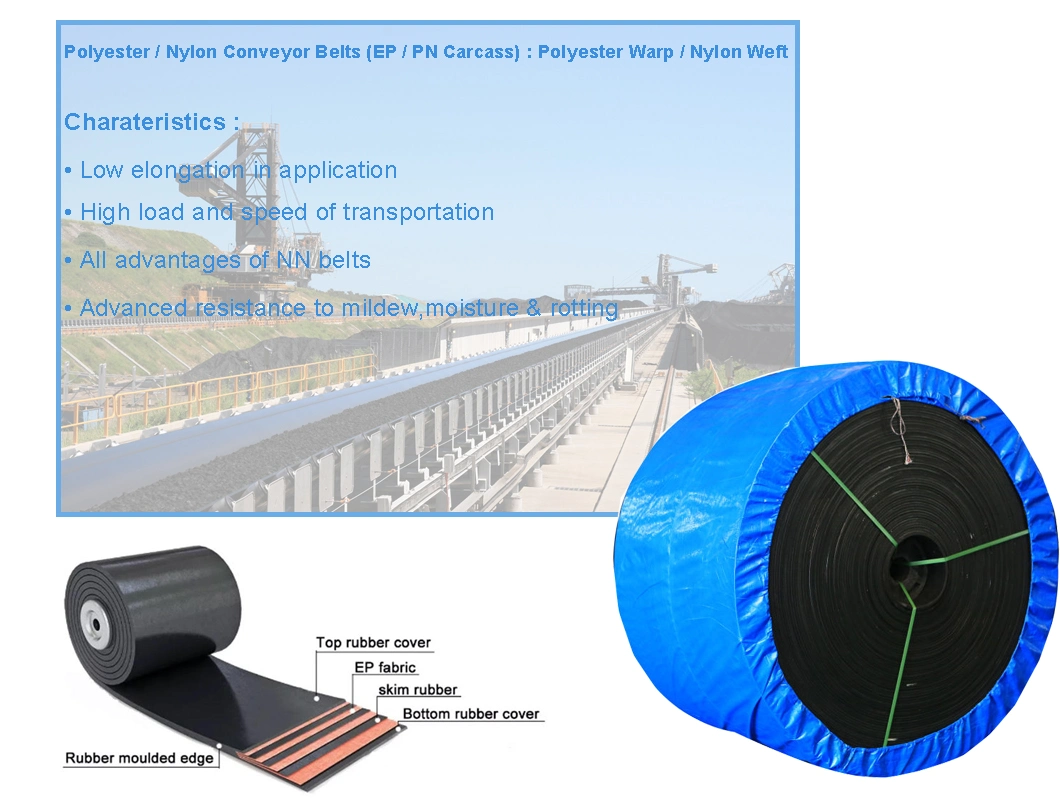

Polyseter Conveyor Belt(EP CONVEYOR BELT)

EP Conveyor Belt is the combination of Polyester in warp and Nylon in weft. EP belt provides far much lower elongation than NN belt and it can also be used for special purposes.

Features of EP Conveyor Belts:

• Plys : 1 - 12

• Top cover thickness : 25.4 mm (1") max

• Edge : Cut edge or moulded edge

• Max width : 4200 mm

• Total thickness : 50 mm (2") max

• Bottom cover thickness : 0 - 25.4 (1") mm

• Max. fabric strength : EP / NN 500

• Belt with cross breakers available

Specification and technical data of multi-ply EP conveyor belt:

Cover Properties of the belts:

Adhesion and elongation of the belt:

Nylon Conveyor Belt (Conveyor Belt)

Polyseter Conveyor Belt(EP CONVEYOR BELT)

EP Conveyor Belt is the combination of Polyester in warp and Nylon in weft. EP belt provides far much lower elongation than NN belt and it can also be used for special purposes.

Features of EP Conveyor Belts:

• Plys : 1 - 12

• Top cover thickness : 25.4 mm (1") max

• Edge : Cut edge or moulded edge

• Max width : 4200 mm

• Total thickness : 50 mm (2") max

• Bottom cover thickness : 0 - 25.4 (1") mm

• Max. fabric strength : EP / NN 500

• Belt with cross breakers available

Specification and technical data of multi-ply EP conveyor belt:

| Fabric Type | Fabric Structure | Fabric Specs | Ply Thickness (mm/p) | Strength Series(N/mm) | Cover Thickness | Width mm | ||||||

| Warp | Wetf | 2ply | 3ply | 4ply | 5ply | 6ply | Upper | Lower | ||||

| Polyester (EP) | Polyester (E) | Polyester (P) | EP-80 | 0.6 | 160 | 240 | 320 | 400 | 480 | 2.0-8 | 0-4.5 | 400-4000 |

| EP-100 | 0.75 | 200 | 300 | 400 | 500 | 600 | ||||||

| EP-150 | 1 | 300 | 450 | 600 | 750 | 900 | ||||||

| EP-200 | 1.25 | 400 | 600 | 800 | 1000 | 1200 | 500-4000 | |||||

| EP-250 | 1.35 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| EP-300 | 1.45 | 600 | 900 | 1200 | 1500 | 1800 | ||||||

| EP-350 | 1.5 | ~ | 1050 | 1400 | 1750 | 2100 | 800-4000 | |||||

| EP-400 | 1.55 | ~ | ~ | 1600 | 2000 | 2400 | 1000-4000 | |||||

| EP-500 | 1.7 | ~ | ~ | 2000 | 2500 | 3000 | ||||||

| Cover Grade | Tensile Strength≥ | Elongation≥ | Abrasion≥ | Change Rate of tensile strength andelongation after aging % | |

| Mpa | kgf/cm2 | ||||

| Heavy(H) | 18 | 180 | 400 | 0.7 | -25 to 25 |

| Medium(M) | 14 | 140 | 350 | 0.8 | -25 to 25 |

| Light(L) | 10 | 100 | 300 | 1 | -30 to 30 |

| Belt Carcass | Adhesive Strength | Elongation | |||

| Between plies N/MM | Between rubber and carcass | Longitudinal elongation at break% ≥ | Longitudinal elongation at load% ≤ | ||

| Rubber thickness≤1.5mm | Rubber Thickness>1.5mm | ||||

| EP | ≥4.05 | ≥3.15 | ≥3.50 | 10 | 1.5 |

Standards Complied :

Our technicians / equipment are trained to manufacture belts as per : DIN 22102 (German), AS 1333 (Australian), SANS 1173 (South African), RMA (US, South America), BS 490 (British), JS (Japanese).

NN Conveyor Rubber Belt is the combination of Nylon in warp and weft and it is widely used in multi-ply conveyor belts for transporting bulk or lumpy materials.

Features of NN conveyor belt:

1. High tensile strength

2. Excellent troughability

3. High resistance against impact

4. Strong adhesion and less ply separation

5. Good accommodation to carrier roller and being well kept straight on

Features of NN conveyor belt:

1. High tensile strength

2. Excellent troughability

3. High resistance against impact

4. Strong adhesion and less ply separation

5. Good accommodation to carrier roller and being well kept straight on

| Ply Thickness (mm/p) | Strength Series | Cover Thickness | Width (mm) | |||||

| 2ply | 3ply | 4ply | 5ply | 6ply | Upper | Lower | ||

| 0.75 | 200 | 300 | 400 | 500 | 600 | 1.5-8 | 0-4.5 | 400-4000 |

| 0.8 | 300 | 450 | 600 | 750 | 900 | |||

| 0.9 | 400 | 600 | 800 | 1000 | 1200 | 500-4000 | ||

| 1.15 | 500 | 750 | 1000 | 1250 | 1500 | |||

| 1.25 | 900 | 1200 | 1500 | 1800 | ||||

| 1.45 | 1600 | 2000 | 2400 | 800-4000 | ||||

| 1.55 | 2000 | 2500 | 3000 | |||||

| Cover Grade | Tensile Strength ≥ | Elongation ≥ | Abrasion ≥ | Change Rate of tensile strength and elongation after aging % | |

| Mpa | kgf/cm2 | ||||

| Heavy(H) | 18 | 180 | 400 | 0.7 | -25 to 25 |

| Medium(M) | 14 | 140 | 350 | 0.8 | -25 to 25 |

| Light(L) | 10 | 100 | 300 | 1 | -30 to 30 |

Adhesion and elongation of the belt:

| Belt Carcass | Adhesive Strength | Elongation | |||

| Between plies N/MM | Between rubber and carcass | Longitudinal elongation at break% ≥ | Longitudinal elongation at load% ≤ | ||

| Rubber thickness≤1.5mm | Rubber Thickness>1.5mm | ||||

| Nylon | ≥4.05 | ≥3.15 | ≥3.50 | 10 | 2 |

High Temperature Resistant Conveyor Belt

Heat resistant conveyor belts are highly resistant to hot material such as cement, steel or sand. The cover rubber of a conveyor belt consists of a special rubber compound featuring high adhesive strength, elongation at break and excellent thermal protection force. Using diverse elastomers heat resistance varies. Heat resistant Ambelt conveyor belts manufactured according to DIN 22102 are able to convey material with a constant temperature of 200°C - short runs also up to 250°C.

Application areas:

Chemical sector

Fertilizer industry

Iron and steel industry

Foundries

Glass industry

Metalworking industry

Waste incineration

Cement plants

Application areas:

Chemical sector

Fertilizer industry

Iron and steel industry

Foundries

Glass industry

Metalworking industry

Waste incineration

Cement plants

| Fabric Type | Fabric Specs | Strength Series | Cover Thickness | Width mm | |||||

| 2ply | 3ply | 4ply | 5ply | 6ply | Upper | Lower | |||

| Polyster (EP) | EP-100 | 200 | 300 | 400 | 500 | 600 | 4.5-10 | 0-4.5 | 400-4000 |

| EP-150 | 300 | 450 | 600 | 750 | 900 | ||||

| EP-200 | 400 | 600 | 800 | 1000 | 1200 | ||||

| EP-250 | 500 | 750 | 1000 | 1250 | 1500 | ||||

| EP-300 | 600 | 900 | 1200 | 1500 | 1800 | ||||

| EP-400 | 800 | 1200 | 1600 | 2000 | 2400 | ||||

| Item | ||

| Hardness | Difference before and after aging(IRHD) | 23 |

| Maximum value after aging (IRHD) | 88 | |

| Tensile Strength | The peformance change rate decreases % | 40 |

| The lowest value after aging,Mpa | 5 | |

| Elongation at break | The change rage of peformance,% | 60 |

| The lowest value after aging,% | 150 | |

Oil Resistant Conveyor Belt:

Special oil resistant compound belt good for carrying materials coated with oil or grease.

Oil and fat resistance can be divided into two categories - mineral oils and vegetable & animal oils and fats. Mineral oils are the most aggressive and demand a particularly high level of protection. Our conveyor belts are featured in three cover grades: MOR, G and ROS. The first offer medium protection against oils while the extremely succesful ROS grade protects the conveyor belt against agressive mineral oils.The carcass is made of polyamide / polyester (EP), polyester/polyester (EE).

Oil and fat resistance can be divided into two categories - mineral oils and vegetable & animal oils and fats. Mineral oils are the most aggressive and demand a particularly high level of protection. Our conveyor belts are featured in three cover grades: MOR, G and ROS. The first offer medium protection against oils while the extremely succesful ROS grade protects the conveyor belt against agressive mineral oils.The carcass is made of polyamide / polyester (EP), polyester/polyester (EE).

| DIN Quality | Tensile Strength | Elongation at break | Abrasion loss | Base ploymer | Technical features Application are |

| MOR | 150 | 350 | 200 | NBR/SBR | Medium oil resistant conveyor belt. Works in temperatures from -30 to 70˚C. |

| G | 150 | 350 | 200 | NBR/SBR | Good oil resistant conveyor belt. Works in temperatures from -30 to 80˚C. |

| ROS | 150 | 350 | 200 | NBR | Excellent mineral oil and fat resistant conveyor belt for extreme working conditions.Works intemperatures from -30 to100˚C. |

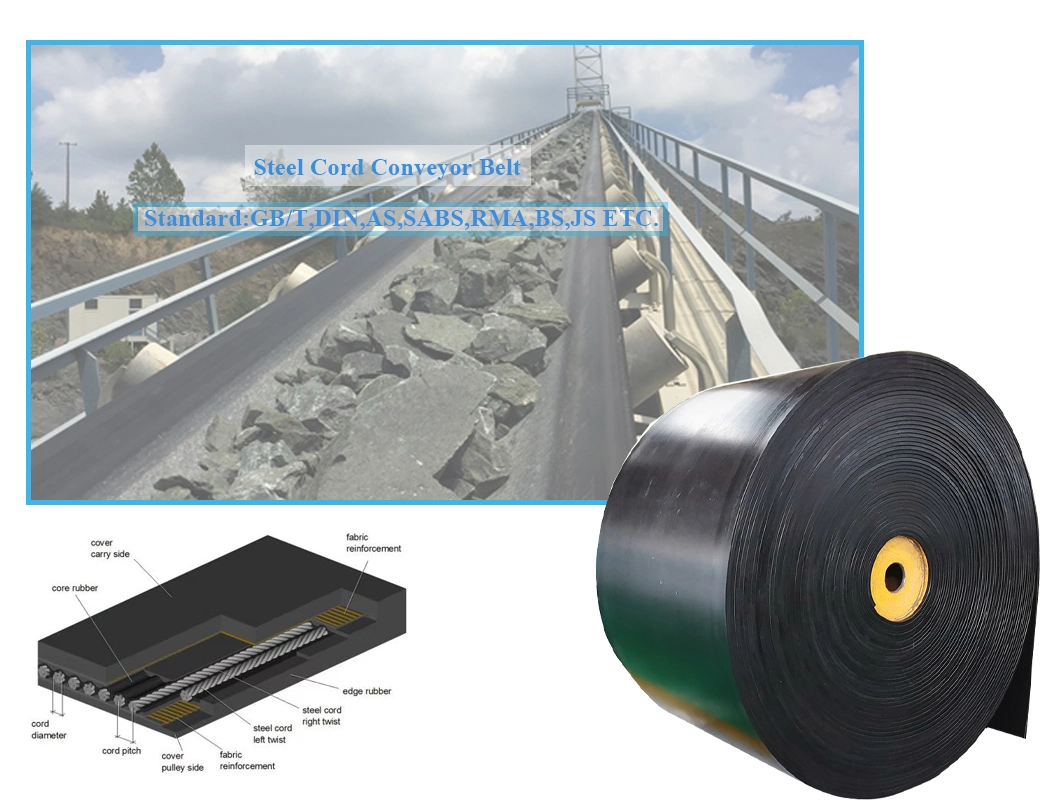

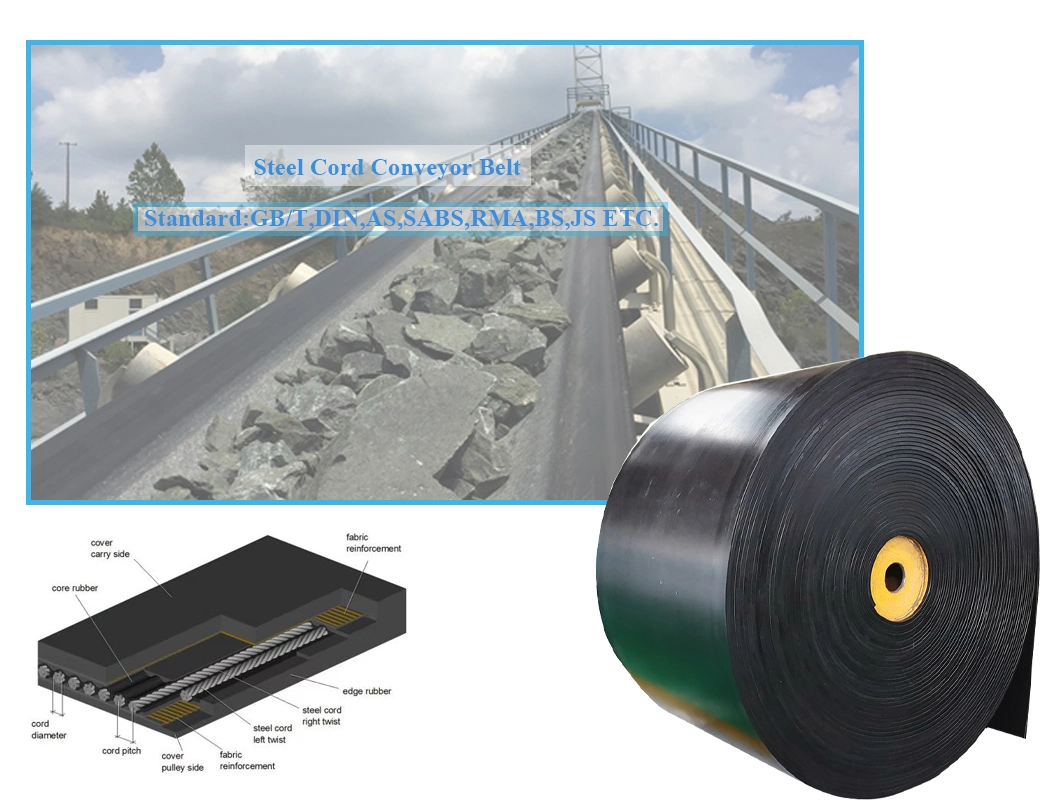

Steel Cored Conveyor Belt  Performance of the Steel Cord Conveyor Belt:

Performance of the Steel Cord Conveyor Belt:

The tear-proof steel cord rubber conveyor belt for coal mining is used for the higher strength, less elongation galvanized steel cord, whose top and bottom surfaces are covered with strengthen transverse carcass and wearied aging-resistant rubber cover. When there is aculeate subject thrust, the belt can be protected and crack extending is prevented.

It can convey materials that require high strength, longevity and less elongation, long distance, good flexibility, good slot molding at the occasion, high speed, large loading, high strength in the field of coal mining, port, electricity, metallurgy, etc.

It can convey materials that require high strength, longevity and less elongation, long distance, good flexibility, good slot molding at the occasion, high speed, large loading, high strength in the field of coal mining, port, electricity, metallurgy, etc.

| TechnicalData | Belt Strength | |||||||||||||

ST/S630 | ST/S800 | ST/S1000 | ST/S1250 | ST/S1600 | ST/S2000 | ST/S2500 | ST/S2800 | ST/S3150 |

| ST/S4000 | ST/S4500 | ST/S5000 | ST/S5400 | |

Longitudinal Tensile Strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| MaxNominal Dia. of Steel Cord (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Steel Cord Pitch (mm) | 10 ±1.5

| 10 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 16 ±1.5 | 17 ±1.5 | 17 ±1.5 |

| Thickness of Top Cover (mm) | 5 | 5 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

Thickness of Bottom Cover(mm) | 5 | 5 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| Width (mm) | Numbers of Steel Cord | |||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 76 | 76 | 76 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 89 | 89 | 89 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 101 | 101 | 101 | 96 | 90 | 90 |

| 1800 | 171 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 114 | 114 | 114 | 109 | 102 | 102 |

| 2000 | 196 | 196 | 159 | 159 | 159 | 159 | 128 | 128 | 128 | 128 | 128 | 121 | 113 | 113 |

| 2200 | 216 | 216 | 176 | 176 | 176 | 176 | 141 | 141 | 141 | 141 | 141 | 134 | 125 | 125 |

| The Recommended Minimum Pulley Diameter | ||||||||||||||

| ST Belt Type | ST/S 630 | ST/S 800 | ST/S 1000 | ST/S 1250 | ST/S 1600 | ST/S 2000 | ST/S 2500 | ST/S 2800 | ST/S 3150 | ST/S 3500 | ST/S 4000 | ST/S 4500 | ST/S 5000 | ST/S 5400 |

Minimum Pulley Diameter (mm)

| 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

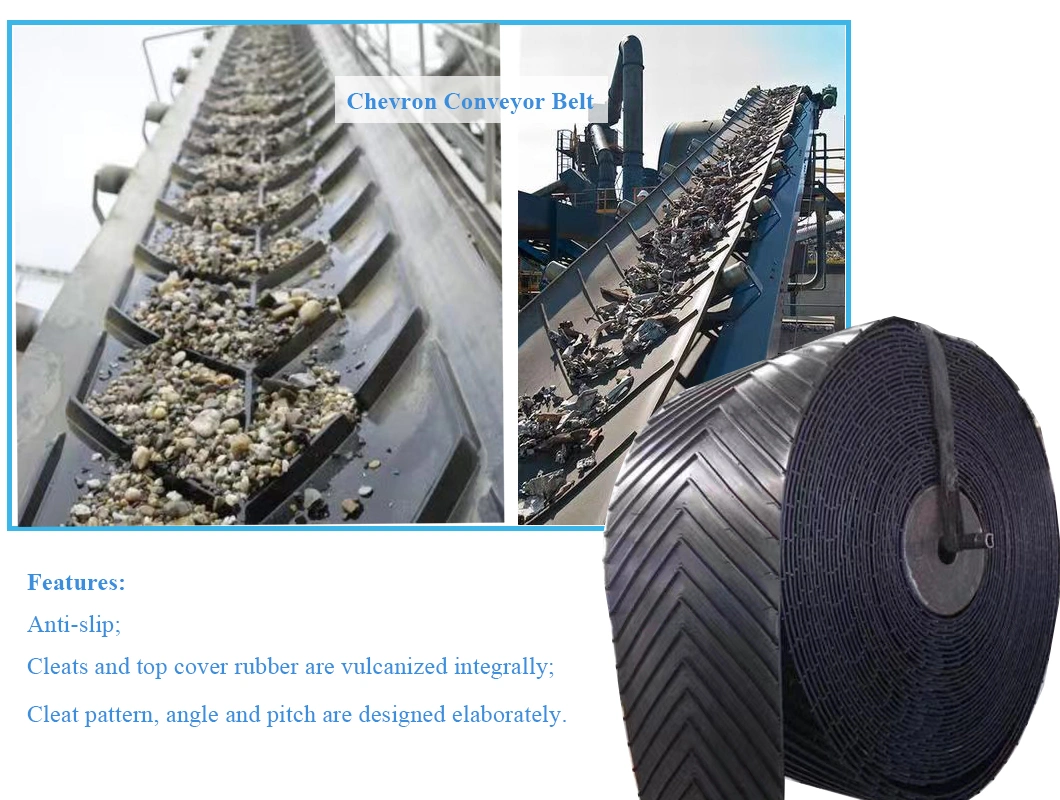

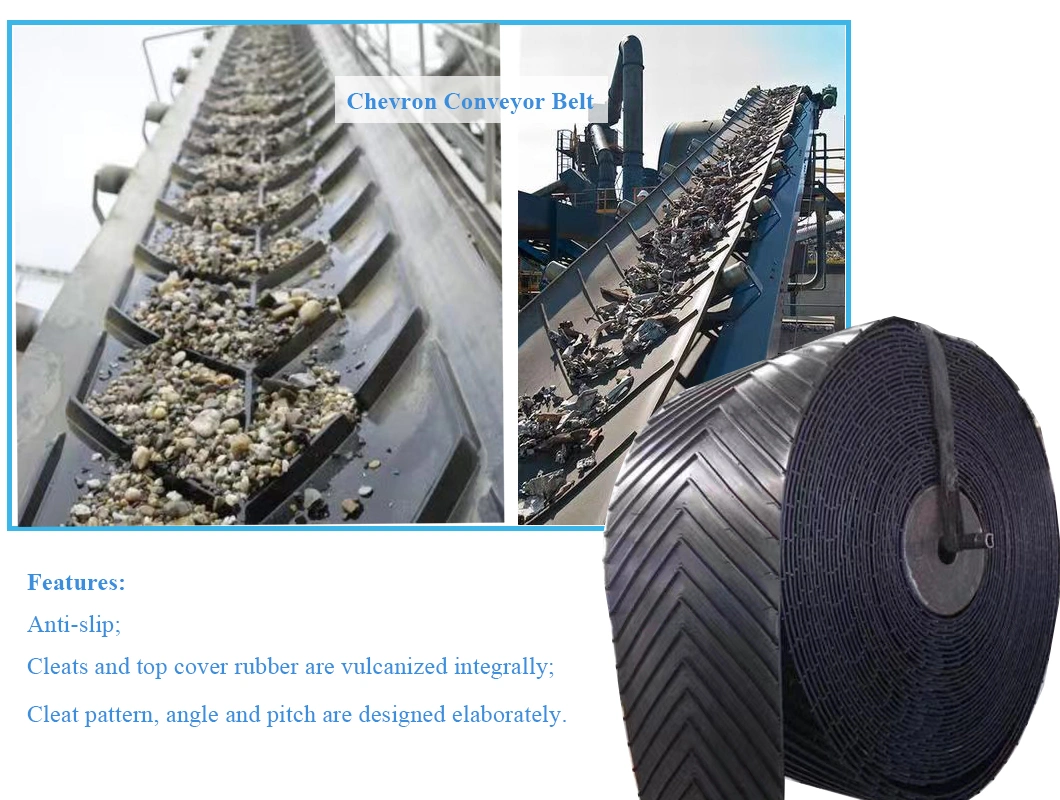

Chevron Conveyor Belt:

Chevron conveyor belt is suitable for conveying loose, bulky or bagged materials on inclined surface at angles of less than 40 degrees.

We could produce chevron belts with type: Open or Close V, Open or close U, Y and Multi V. OEM are welcome.

Uses

Chevron (patterned) conveyor belt mainly conveys powder, granulated, and small lump materials at the inclination of no more than 40º. It can also convey packaged material.

We could produce chevron belts with type: Open or Close V, Open or close U, Y and Multi V. OEM are welcome.

Uses

Chevron (patterned) conveyor belt mainly conveys powder, granulated, and small lump materials at the inclination of no more than 40º. It can also convey packaged material.

Selection the type and height of cleats depends on the material to be conveyed and the angle of inclination:

| Type of material | Material example | Max. angle of inclination | |||

| Height of cleats | |||||

| H(mm): | H(mm): | H(mm): | H(mm): | ||

| 14 | 16 | 25 | 32 | ||

| Powdery | Flour, etc. | 25° | 25° | 28° | 30° |

| Loose flowing | Corn, barley, wheat, rye, etc. | 20/25° | 20/25° | 25/30° | 25/30° |

| Loose rolling | Gravel, ground stone, etc. | 25° | 25° | 28° | 30° |

| Sticky | Wet sand, ash, wet loam, etc. | 30° | 30/35° | 35/40° | 40/45° |

| Packed | Sacks, paper sacks, etc. | 30/35° | 30/35° | 35/40° | 35/40° |

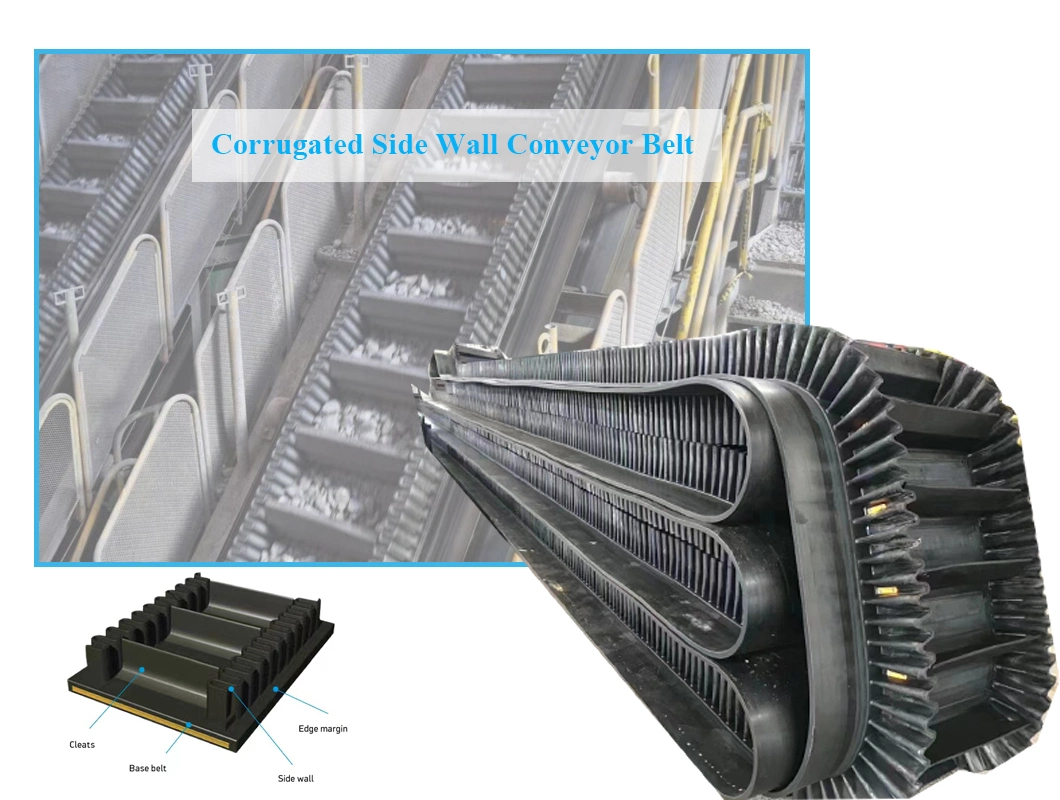

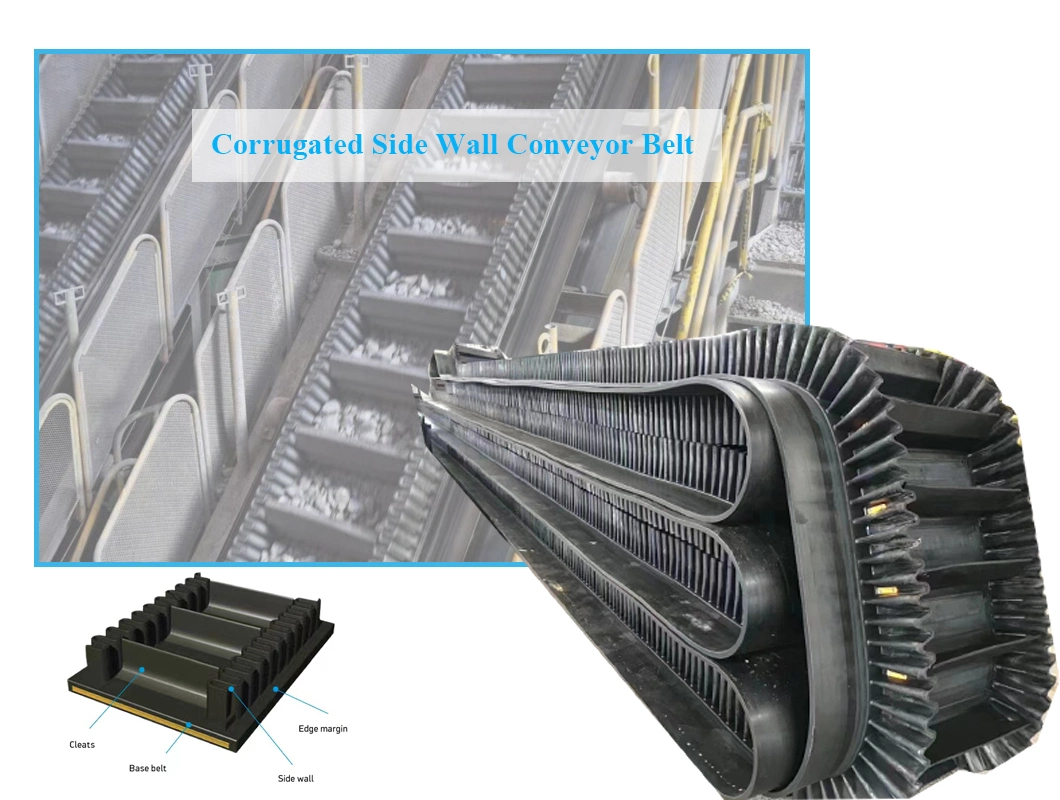

Corrugated Sidewall Conveyor Belt

Corrugated sidewall belts are ideal for transporting bulk goods efficiently on uphill and downhill gradients.

Applications:

1. Coal and wood-chip fired power stations

2. Underground mining (coal and ore)

3. Shaft conveying for tunnelling and underground mining

4. Steel industry

5. Ship loading and unloading, ship to ship loading

6. Sand preparation in foundry plants

7. Silo feeding

8. Slope conveying in openpit mining

9. Waste recycling, soil purification and water treatment

Applications:

1. Coal and wood-chip fired power stations

2. Underground mining (coal and ore)

3. Shaft conveying for tunnelling and underground mining

4. Steel industry

5. Ship loading and unloading, ship to ship loading

6. Sand preparation in foundry plants

7. Silo feeding

8. Slope conveying in openpit mining

9. Waste recycling, soil purification and water treatment

NN/CC/EP/Steel cord/corrugated side wall/OEM:

Package of conveyor belt:

Poduction and testing equipments:

Poduction and testing equipments:

Conveyor Rubber Belt Application:

Company Certificates:

Company Certificates: