- Overview

- Packaging & Shipping

Basic Info.

Model NO.

Cr-00139

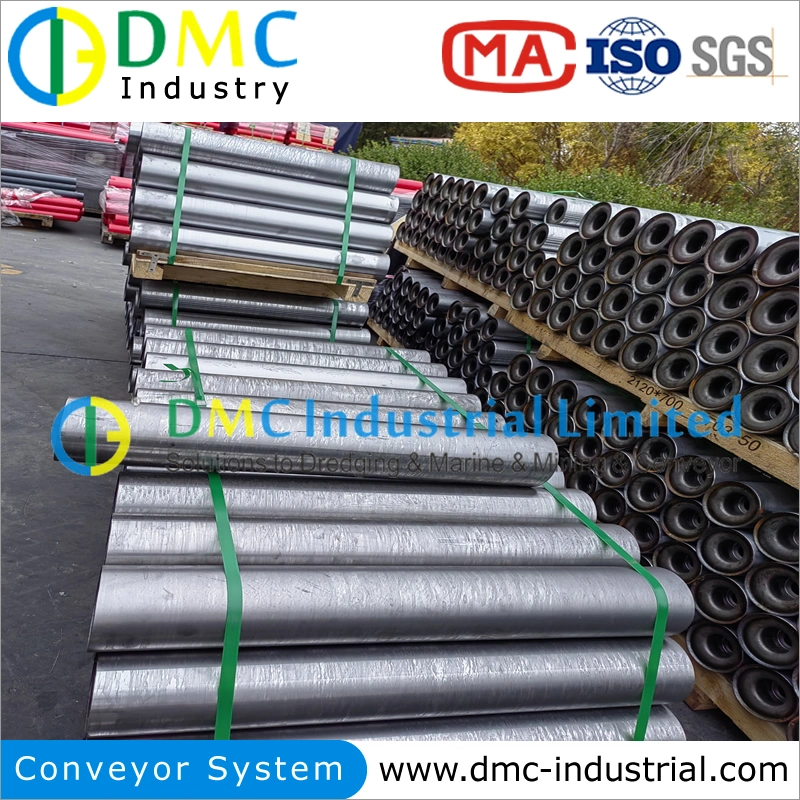

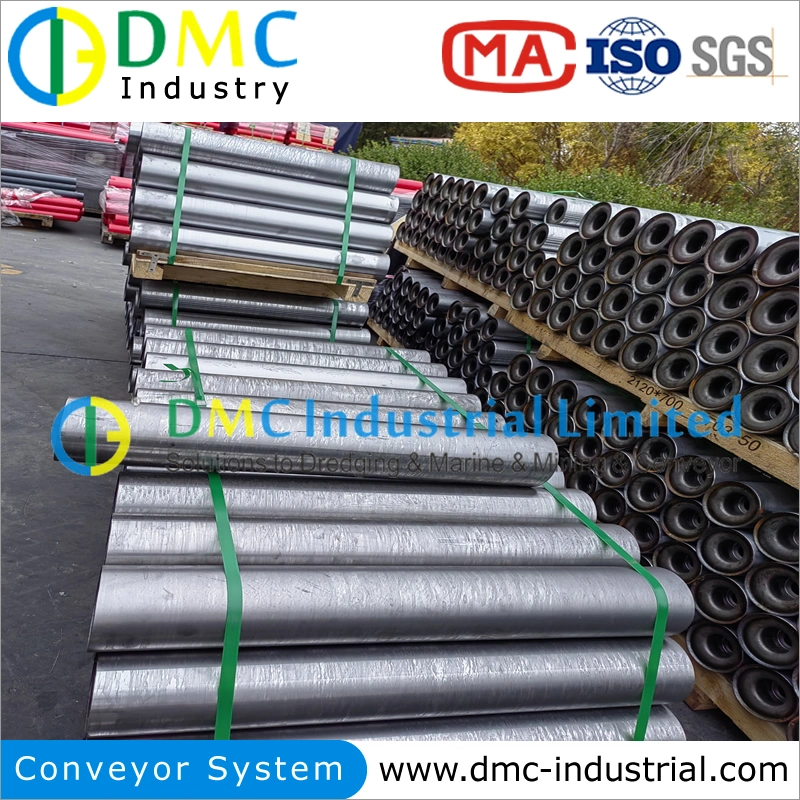

Color

Paint

Treatment

Galvanized, Zinc Plating

Lagging

Rubber, PU, PVC

Transport Package

Wooden Crate

Specification

ISO9001

Trademark

DMC

Origin

Shanghai, China

HS Code

8431390000

Production Capacity

1000, 000 PCS/Year

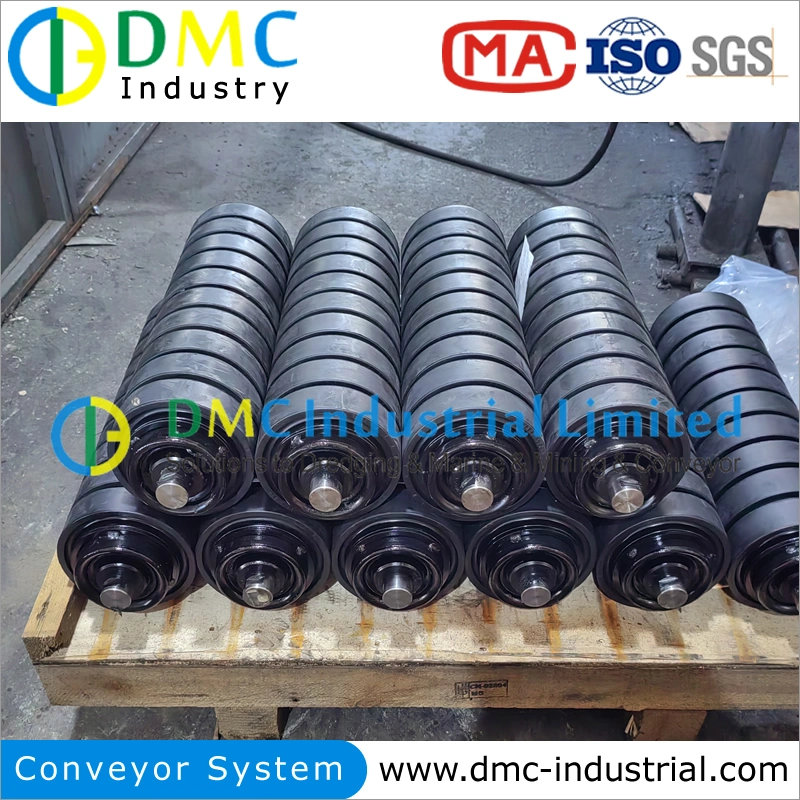

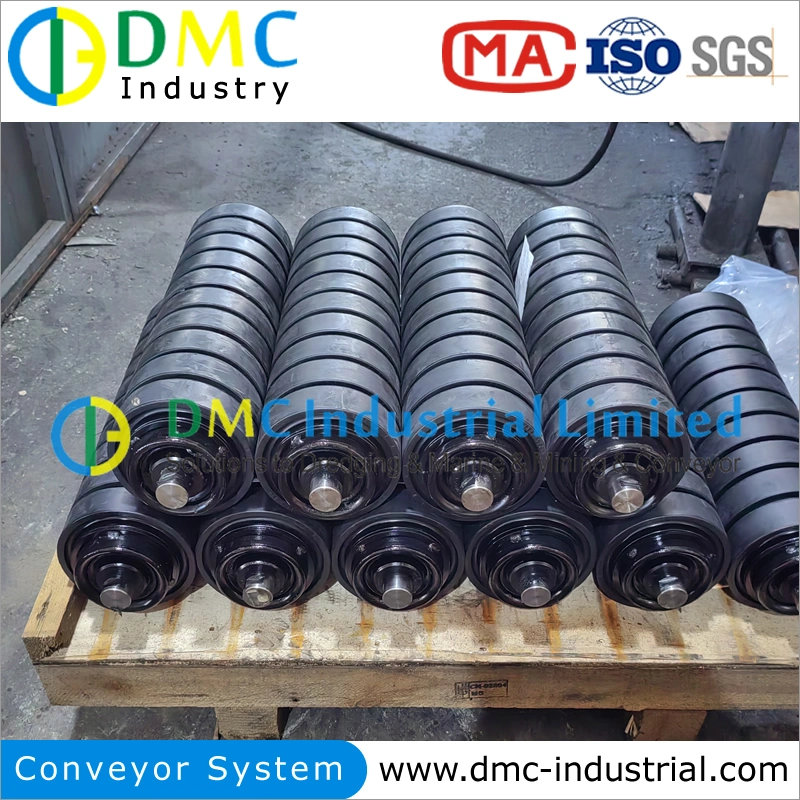

Product Description

CONVEYOR ROLLERS,CONVEYOR IDLERS,CONVEYOR SPARE PARTS, CONVEYOR DRUMS PULLEYS,GALVANIZED FRAMES FOR BULK MATERIAL HANDLING PROJECTS

Advantages and Benefits:

1, Solid design for heavy duty roller.

2, Waterproof and dustproof design

3, Low indicated run out (T.I.R) , good balance, stable operation .

4, Low resistance for start and friction, high efficiency and energy saving.

5, The bearing house and tube are assembled and welded with a concentric automatic welding machine.

6, Cutting of steel tube and shaft is performed with digital auto equipment.

7, Fabrication of roller is effected by an auto device.

8, The conveyor rollers are manufactured accoding to CEMA,ASTM,DIN standard.

9, The conveyor roller is lubricated and free from maintenance.

Raw material and specifications are as below:

A:Shaft is made from cool drawn steel, cut and machined by automatic numerically controlled machines, the concentricity in 0.05mm.

B:The tube is made from ST37-2 DIN standard and machined by automatic numerically controlled machines.

C:Bearing are deep groove precision ball bearing with C3 internal clearance.

D:Bearing house are made from cold-forming and machinesd by automatic numerically controlled machines

E:The seals are triple labyrinth seals and made from nylon PA6 material.

F:The grease uses 2,3 grade long-lasting lithium grease.

Advantages and Benefits:

1, Solid design for heavy duty roller.

2, Waterproof and dustproof design

3, Low indicated run out (T.I.R) , good balance, stable operation .

4, Low resistance for start and friction, high efficiency and energy saving.

5, The bearing house and tube are assembled and welded with a concentric automatic welding machine.

6, Cutting of steel tube and shaft is performed with digital auto equipment.

7, Fabrication of roller is effected by an auto device.

8, The conveyor rollers are manufactured accoding to CEMA,ASTM,DIN standard.

9, The conveyor roller is lubricated and free from maintenance.

Raw material and specifications are as below:

A:Shaft is made from cool drawn steel, cut and machined by automatic numerically controlled machines, the concentricity in 0.05mm.

B:The tube is made from ST37-2 DIN standard and machined by automatic numerically controlled machines.

C:Bearing are deep groove precision ball bearing with C3 internal clearance.

D:Bearing house are made from cold-forming and machinesd by automatic numerically controlled machines

E:The seals are triple labyrinth seals and made from nylon PA6 material.

F:The grease uses 2,3 grade long-lasting lithium grease.

| Technical Parameters | ||||

| Standard Diameter | Length scope ( mm) | Bearings Type (Min~Max) | Idler's Shell Wall Thickness | |

| mm | Inch | |||

| 63.5 | 2 1/2 | 150~3500 | 204 | 3.0mm~3.75mm |

| 76 | 3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 89 | 3 1/3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 102 | 4 | 150~3500 | 204 205 305 | 3.5mm~4.0mm |

| 108 | 4 1/4 | 150~3500 | 204 205 305 306 | 3.5mm~4.0mm |

| 114 | 4 1/2 | 150~3500 | 205 206 305 306 | 3.5mm~4.5mm |

| 127 | 5 | 150~3500 | 204 205 305 306 | 3.5mm~4.5mm |

| 133 | 5 1/4 | 150~3500 | 205 206 207 305 306 | 3.5mm~4.5mm |

| 140 | 5 1/2 | 150~3500 | 205 206 207 305 306 | 3.5mm~4.5mm |

| 152 | 6 | 150~3500 | 205 206 207 305 306 307 308 | 4.0mm~4.5mm |

| 159 | 6 1/4 | 150~3500 | 205 206 207 305 306 307 308 | 4.0mm~4.5mm |

| 165 | 6 1/2 | 150~3500 | 207 305 306 307 308 | 4.5mm~6.0mm |

| 177.8 | 7 | 150~3500 | 207 306 307 308 309 | 4.5mm~6.0mm |

| 190.7 | 7 1/2 | 150~3500 | 207 306 307 308 309 | 4.5mm~6.0mm |

| 194 | 7 5/8 | 150~3500 | 207 307 308 309 310 | 4.5mm~6.0mm |

| 219 | 8 5/8 | 150~3500 | 308 309 310 | 4.5mm~6.0mm |

Typical applicatios:Mining---coal, iron ore,gold,Coal process plants,Coal fired power stations,Import/export terminals,Steel plants,Fertilizer plants,Cement plants,Gravel plants,Quarry.