Basic Info.

Steel

Q235/Q355

Finished

HDG/Painted

Usage

Formwork

Function

Shoring System

Transport Package

Normal Package

Specification

900MM

Trademark

OEM/ODM

Origin

China

HS Code

73084000

Production Capacity

500 Ton / Month

Product Description

frame building steel Best System h beam accessories

Mega beam is a versatile temporary modular heavy-duty propping system that can be adapted to the most demanding projects on construction sites. Its most frequent uses are the support of bridges, superstructures and ground shoring applications.

It is one of the fastest, most efficient and versatile ways to provide quick support and access solutions in a wide variety of situations, using only two main components, the base jack and heavy-duty mega beam. This comes complete with a variety of additional propping and shoring equipment.

Features & Benefits

Nine standard lengths, from 3.5in(90mm) to 212.6in (5400mm), with a board choice of accessories. Mega beam can be assembled into towers, props and beams of nearly any length.

1000kN massive axial load capacity and high axial stiffness. Mega beam can be adapted to the demands of heavy formwork, cofferdams, bridge decks and more.

Mega beam 1000 can be used as the backbone of the bridge with minimal traffic flow disruption.

Using accurate welding jigs, manufactured from high-yield, combining maximum durability and load capacity with reduced unit weight, complete by hot dip galvanizing, eliminates corrosion and minimizes maintenance.

The Mega beam system is engineered to minimize labor costs, increase site productivity, improve work site safety and meet the requirements of current construction and civil engineering techniques.

Mega beam must always be used by experienced personnel and have multi-directional support.

Applications

Mega beam temporary sections, which are robust and easy to assemble, can be used in many temporary work applications such as:

Cofferdams

Bridge propping and hydraulic jacking

Façade retention

Ground shoring and excavation support

Construction of lifting rigs

When used in conjunction with Waler beam or soldiers stadium roof supports

Travelling slab and tunnel formwork

Heavy duty falsework

1 DKS Mega Beam 1000

2. Screw Jack

3. Rocking Head

4. Jack Plate

5. Brace Plate

Mega beam welding Jig

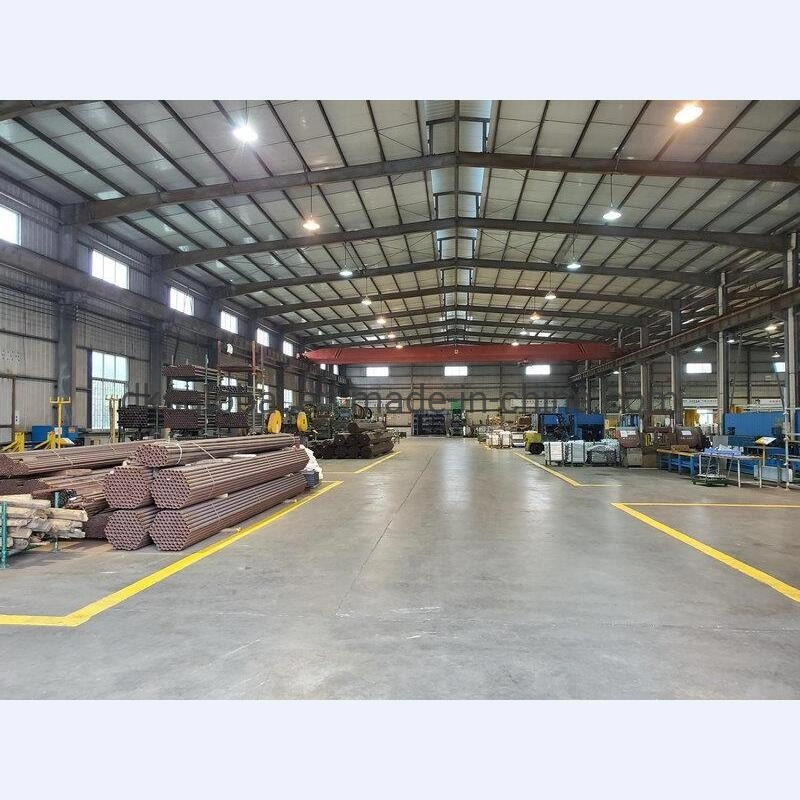

Factory

Located in Guangdong, the factory cover an area of 16,528 M2 and is specialized in the production of shoring and safety systems.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

Products including shoring system, scaffolding system, formwork system, and other components for construction site.

system, scaffolding system, formwork system, and other components for construction site.

And products are exported to Japan, the United States, Canada, Germany, Spain and many other countries.

Mega beam is a versatile temporary modular heavy-duty propping system that can be adapted to the most demanding projects on construction sites. Its most frequent uses are the support of bridges, superstructures and ground shoring applications.

It is one of the fastest, most efficient and versatile ways to provide quick support and access solutions in a wide variety of situations, using only two main components, the base jack and heavy-duty mega beam. This comes complete with a variety of additional propping and shoring equipment.

Features & Benefits

Nine standard lengths, from 3.5in(90mm) to 212.6in (5400mm), with a board choice of accessories. Mega beam can be assembled into towers, props and beams of nearly any length.

1000kN massive axial load capacity and high axial stiffness. Mega beam can be adapted to the demands of heavy formwork, cofferdams, bridge decks and more.

Mega beam 1000 can be used as the backbone of the bridge with minimal traffic flow disruption.

Using accurate welding jigs, manufactured from high-yield, combining maximum durability and load capacity with reduced unit weight, complete by hot dip galvanizing, eliminates corrosion and minimizes maintenance.

The Mega beam system is engineered to minimize labor costs, increase site productivity, improve work site safety and meet the requirements of current construction and civil engineering techniques.

Mega beam must always be used by experienced personnel and have multi-directional support.

Applications

Mega beam temporary sections, which are robust and easy to assemble, can be used in many temporary work applications such as:

Cofferdams

Bridge propping and hydraulic jacking

Façade retention

Ground shoring and excavation support

Construction of lifting rigs

When used in conjunction with Waler beam or soldiers stadium roof supports

Travelling slab and tunnel formwork

Heavy duty falsework

1 DKS Mega Beam 1000

| Code | Description | Weight | ||

| DMB5400 | 212.6in | MB leg 5400mm | 696.7lb | 316.0kg |

| DMB4500 | 177.2in | MB leg 4500mm | 586.4lb | 266.0kg |

| DMB2700 | 106.3in | MB leg 2700mm | 352.7lb | 160.0kg |

| DMB1800 | 70.9in | MB leg 1800mm | 246.9lb | 112.0kg |

| DMB0900 | 35.4in | MB leg 900mm | 143.3lb | 65.0kg |

| DMB0450 | 17.7in | MB leg 450mm | 99.2lb | 45.0kg |

| DMB0270 | 10.6in | MB leg 270mm | 77.2lb | 35.0kg |

| DMB0090 | 3.5in | MB leg 90mm | 55.1lb | 25.0kg |

| DMB0015 | 0.6in | MB leg 15mm E/P | 22.0lb | 10.0kg |

2. Screw Jack

| Code | Description | Weight | |

| DMB1000 | Screw Jack | 119.1lb | 54.02kg |

3. Rocking Head

| Code | Description | Weight | |

| DMB03 | Rocking Head | 103.6lb | 47.0kg |

4. Jack Plate

| Code | Description | Weight | |

| DMB01 | Jack Plate | 44.8lb | 20.3kg |

5. Brace Plate

| Code | Description | Weight | |

| DMB02 | Brace Plate | 44.1lb | 20.0kg |

Mega beam welding Jig

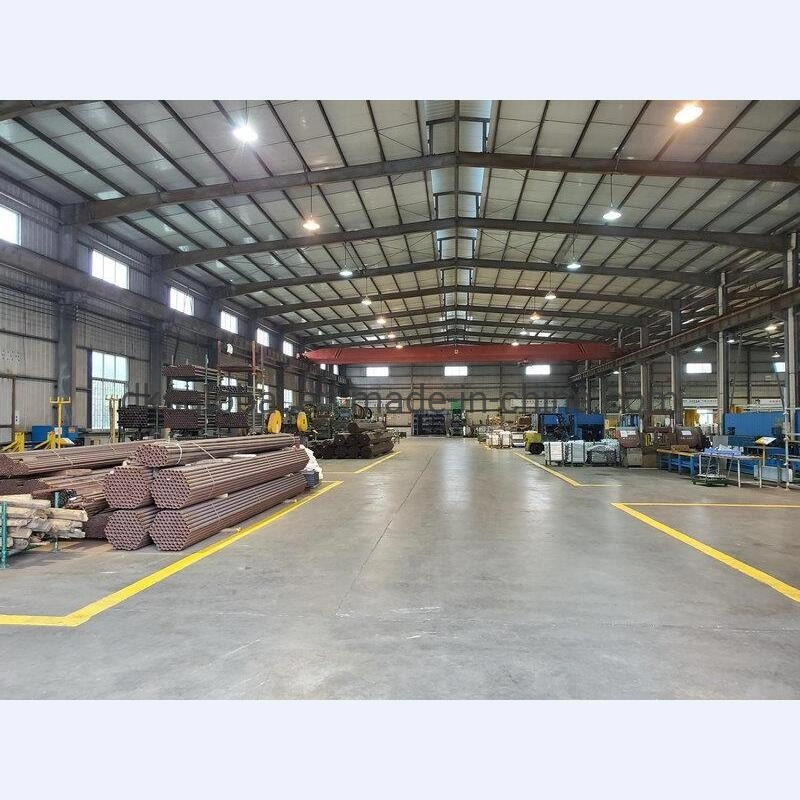

Factory

Located in Guangdong, the factory cover an area of 16,528 M2 and is specialized in the production of shoring and safety systems.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

Products including shoring

system, scaffolding system, formwork system, and other components for construction site.

system, scaffolding system, formwork system, and other components for construction site. And products are exported to Japan, the United States, Canada, Germany, Spain and many other countries.